-

info@jlamtech.com

-

0510-83555850

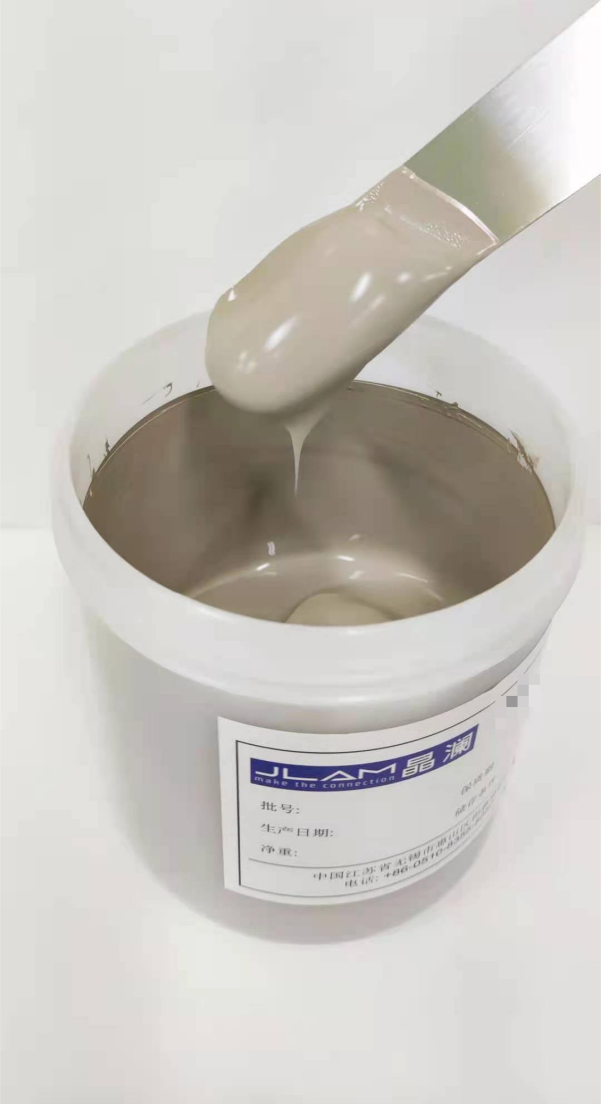

Conductive Silver Paste for Solar Cells

/ Solar conductive silver pasteConductive silver paste for solar cells, as a metallised electrode material, is the key to improving the photoelectric conversion efficiency of solar cells and is a favourable guarantee for the reliability of photovoltaic modules.

Every major change in solar cell technology has been accompanied by technological advances in PV conductive silver paste; the upgrading of conductive silver paste has also made possible every technological innovation in solar cells. From upstream silicon materials to downstream photovoltaic power plant applications, the technological innovation of conductive silver paste and solar cell industry chain is closely related to each link.

For our PV customers, we focus on technological innovation at the application end. We provide customized total solutions for the diverse cell technology paths of the PV industry.

Fine grate slurry:

1. The innovative organic system provides excellent rheological properties for the paste, enabling ultra-fine line (<10um) printing, excellent aspect ratios and consistent long-term print performance

2. A comprehensive range of products to meet various line square resistance requirements up to (>190Ω) for excellent contact performance

3. break through the technical barriers of imported silver powder, own silver powder can meet the mainstream efficiency requirements and printing performance

Fine grille on the front

1. The inorganic system can take into account the technical requirements of "high contact, low compound" and has a wider sintering window compatible with production fluctuations, achieving simultaneous improvement in overall line efficiency and yield rate

2. All products are customised to provide the optimum technical solution for different film structures and concentration variations

3. The unique organic system solves the problem of TOPCon frontal ultra-fine line printing and line width control, improves the overall TOPCon screen printing quality and provides room for further cost reduction and improved efficiency performance.

Thin grille on the back:

1. All products on the back side of TOPCon are custom developed to provide optimal products based on the Poly-Si layer, fleece structure and process characteristics to achieve the balance of lowest contact resistance and damage for the best efficiency performance.

1. Lower body and contact resistance, high speed fine line printing and fast curing capability

2. All-round low-temperature welding solutions in combination with existing component solar ribbon technology

3. Excellent long-term cell and module reliability

Main fence:

1.A mature and complete product range featuring low unit consumption, high tensile strength and good solderability and resistance, with matching product solutions for different contact requirements.

Close pop-ups

Close pop-ups